Welcome To

PPAP Documents

On this site, you will find lots of information on building or updating a complete PPAP. This site includes PPAP information, different levels of PPAP that can be requested, examples of submissions, training providers and a checklist to make sure your Production Part Approval Process is correct.

From initial design to full production approval

The Production Part Approval Process (PPAP) is a structured method used to ensure that manufacturing processes consistently produce parts that meet all customer engineering and quality requirements. Most commonly applied within the automotive and advanced manufacturing supply chains, PPAP provides confidence that suppliers can deliver conforming parts at scale, every time.

By documenting design intent, process controls, and validation results, PPAP reduces risk before mass production begins. It creates a clear, auditable trail that demonstrates compliance, capability, and readiness. Helping both suppliers and customers avoid costly issues later in the production lifecycle.

A few topics we discuss with our experienced guests:

PPAP Documents List

A complete PPAP submission is made up of multiple documents that collectively demonstrate product conformity, process capability, and manufacturing readiness. Below is an overview of the key PPAP elements and their purpose within the approval process.

| PPAP Document | Summary | View More |

|---|---|---|

| Part Submission Warrant (PSW) | Formal declaration that all PPAP requirements have been met and the part is approved for production. | View more |

| Design Records | Drawings and specifications defining the approved design requirements for the part. | View more |

| Authorised Engineering Change Documents | Records of approved changes to design or process specifications. | View more |

| Engineering Approval | Customer approval where full PPAP submission is not required. | View more |

| DFMEA | Identifies and mitigates potential failures related to part design. | View more |

| Process Flow Diagram | Visual map of the manufacturing process from start to finish. | View more |

| PFMEA | Identifies and mitigates potential failures within the manufacturing process. | View more |

| Control Plan | Defines controls used to ensure consistent product and process quality. | View more |

| Measurement System Analysis (MSA) | Verifies accuracy and reliability of measurement and inspection systems. | View more |

| Dimensional Results | Confirms all part dimensions meet design specifications. | View more |

| Material / Performance Test Records | Evidence that materials and parts meet required specifications. | View more |

| Initial Process Studies | Demonstrates statistical process capability during initial production. | View more |

| Qualified Laboratory Documentation | Confirms testing labs meet customer and industry requirements. | View more |

| Appearance Approval Report (AAR) | Approval for parts where visual appearance is critical. | View more |

| Sample Production Parts | Physical parts submitted for customer validation and approval. | View more |

| Master Sample | Retained reference sample defining acceptable product characteristics. | View more |

| Checking Aids | Gauges and fixtures used to verify product conformity. | View more |

| Customer-Specific Requirements | Additional OEM requirements beyond standard AIAG PPAP elements. | View more |

Our latest podcast episodes

Lorem ipsum amet elit morbi dolor tortor. Vivamus eget mollis nostra ullam corper pharetra torquent auctor metus felis nibh velit. Natoque tellus semper taciti nostra semper montes.

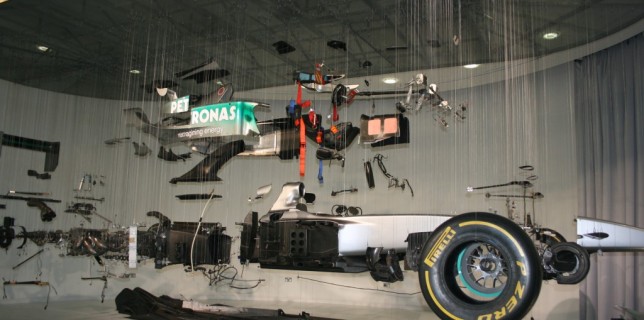

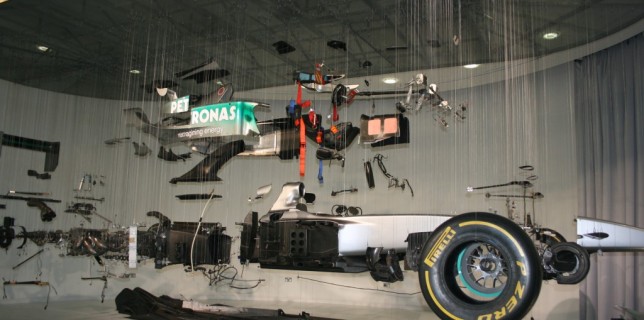

Gold Lamborghini Aventador LP 700-4

Automotive Supplier Improves Quality

General Motors Recall Estimated Cost of $80 Million

Dainese Airbag Suit

Five Facts About Automotive Steel

Defective Materials and Products: A Supply Chain Risk

Are You PPAP Ready?

Supply Chain Corporate Responsibility eLearning

When should you do a PPAP?

Elements of the PPAP

The Purpose of a PPAP

What is a PPAP?

Sign up for Automotive updates

Join the automotive and quality professionals receiving updates on PPAP, APQP, and supplier quality best practices.